August 16, 2011

the floors - part one

I'm about a week behind with construction updates... deadlines at work...

Monday, August 8th

... the moisture content of the wood and subfloor finally dropped to acceptable levels! Hallelujah!

Installation took 2 1/2 days...

... as throughout the rest of the house, White Oak is the wood of choice... when you have a piano and a St. Bernard, you go for the strongest and most durable wood species... no questions asked...

... the staircase, however, is a combination of Red Oak and Poplar. We ended up going with Red Oak for the treads and newel post since the original wood paneling is Red Oak... we wanted to stay consistent... 'softness' isn't a big deal for the stairs. In appearance, the only major difference between the treads and the floors is that the treads will show more 'graining pattern' once stained...

... we are still trying to figure out what to do for a handrail and upstairs guardrail.

Wednesday, August 10th

Installation complete and sanding has begun...

... sanding the stairs and floors took about 1 1/2 days.

We have a couple critical details to figure out in the vestibule... first being the front door threshold. The floor is approximately 1/2" below the original stone threshold... originally the floor in the vestibule was approximately 1/2" higher than the floor in the living room... that is not the case any longer. A transitional wood threshold piece would not have worked... so, what to do...

... not much? The second detail is the front door framing... big gaps all around the door. We need to get some weather stripping, specifically some type of metal stripping for the threshold... otherwise we'll have a wind blown snow bank inside the vestibule, like we did last winter...

Thursday, August 11th

1/2 day of sanding and 1/2 day staining the floors... but...

... which stain color do we go with... Neutral, like the Kitchen and Dining Room? or Rosewood, like the upstairs... which means refinishing the Dining Room and Kitchen? We've been chewing on this decision since July 5th... Rosewood or Neutral? Neutral or Rosewood? Bryan favoring Neutral... I favoring Rosewood... yet both unconvinced...

... when we did the floors upstairs, we went with Rosewood. The upstairs is quite bright, lots of sunlight thanks to plentiful windows and skylights... the Rosewood stain seemed fitting for the house... rich in color... suited for our urban turn-of-the-century rowhouse. However, when we started working on the downstairs, we were concerned the Rosewood would be too dark... the downstairs didn't have as much sunlight as the upstairs (no longer the case... we added 5 windows)... and with the kitchen cabinets being Cherry, we thought having Neutral White Oak floors would be a nice contrast, plus 'lighten' the space...

Neutral

Rosewood

... we figured we could either refinish the upstairs floors or transition with the stairs somehow, the upstairs floors one color and the entire downstairs another... it wouldn't be that bad, especially since both are the same type of wood... but then we really started thinking about it... refinishing the upstairs floors was out of the question... and having one color upstairs and another downstairs... it would bother us... I know it would... so Rosewood won... even though it meant refinishing the dining room and kitchen floors...

... same selections as upstairs... stain is a dry application (wet application = two shades darker) of one coat of Dura Seal Penetrating Finish in Rosewood and finish is two coats of Dura Seal Polyurethane. Downstairs we had gone with water based vs polyurethane... big mistake. After 2 1/2 years, the floors look worn... kind of glad we are refinishing them!

Friday, August 12th

First coat of polyurethane...

Saturday, August 13th

Buffing and second coat of polyurethane were supposed to happen... however the polyurethane was not dry enough, and Rob was concerned about damaging the stain... so...

Monday, August 15th

Buffing and second coat of polyurethane applied...

... pretty!

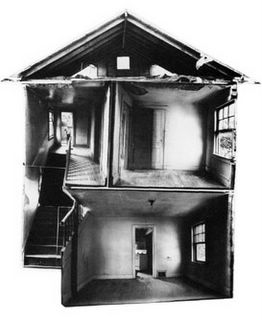

The photo does not do the floors justice... however, since at the time this photo was taken we could not walk on the floors yet, my camera angle was a bit limited.

I kind of don't want to move much furniture back in... maybe just a chair and side table... but such is not the case, since this morning all the furniture we had moved into the dining room and kitchen, and more, moved back into the living room so that Rob could start sanding and staining the other half of the first floor...

Monday, August 8th

... the moisture content of the wood and subfloor finally dropped to acceptable levels! Hallelujah!

Installation took 2 1/2 days...

... as throughout the rest of the house, White Oak is the wood of choice... when you have a piano and a St. Bernard, you go for the strongest and most durable wood species... no questions asked...

... the staircase, however, is a combination of Red Oak and Poplar. We ended up going with Red Oak for the treads and newel post since the original wood paneling is Red Oak... we wanted to stay consistent... 'softness' isn't a big deal for the stairs. In appearance, the only major difference between the treads and the floors is that the treads will show more 'graining pattern' once stained...

... we are still trying to figure out what to do for a handrail and upstairs guardrail.

Wednesday, August 10th

Installation complete and sanding has begun...

... sanding the stairs and floors took about 1 1/2 days.

We have a couple critical details to figure out in the vestibule... first being the front door threshold. The floor is approximately 1/2" below the original stone threshold... originally the floor in the vestibule was approximately 1/2" higher than the floor in the living room... that is not the case any longer. A transitional wood threshold piece would not have worked... so, what to do...

... not much? The second detail is the front door framing... big gaps all around the door. We need to get some weather stripping, specifically some type of metal stripping for the threshold... otherwise we'll have a wind blown snow bank inside the vestibule, like we did last winter...

Thursday, August 11th

1/2 day of sanding and 1/2 day staining the floors... but...

... which stain color do we go with... Neutral, like the Kitchen and Dining Room? or Rosewood, like the upstairs... which means refinishing the Dining Room and Kitchen? We've been chewing on this decision since July 5th... Rosewood or Neutral? Neutral or Rosewood? Bryan favoring Neutral... I favoring Rosewood... yet both unconvinced...

... when we did the floors upstairs, we went with Rosewood. The upstairs is quite bright, lots of sunlight thanks to plentiful windows and skylights... the Rosewood stain seemed fitting for the house... rich in color... suited for our urban turn-of-the-century rowhouse. However, when we started working on the downstairs, we were concerned the Rosewood would be too dark... the downstairs didn't have as much sunlight as the upstairs (no longer the case... we added 5 windows)... and with the kitchen cabinets being Cherry, we thought having Neutral White Oak floors would be a nice contrast, plus 'lighten' the space...

Neutral

Rosewood

... we figured we could either refinish the upstairs floors or transition with the stairs somehow, the upstairs floors one color and the entire downstairs another... it wouldn't be that bad, especially since both are the same type of wood... but then we really started thinking about it... refinishing the upstairs floors was out of the question... and having one color upstairs and another downstairs... it would bother us... I know it would... so Rosewood won... even though it meant refinishing the dining room and kitchen floors...

... same selections as upstairs... stain is a dry application (wet application = two shades darker) of one coat of Dura Seal Penetrating Finish in Rosewood and finish is two coats of Dura Seal Polyurethane. Downstairs we had gone with water based vs polyurethane... big mistake. After 2 1/2 years, the floors look worn... kind of glad we are refinishing them!

Friday, August 12th

First coat of polyurethane...

Saturday, August 13th

Buffing and second coat of polyurethane were supposed to happen... however the polyurethane was not dry enough, and Rob was concerned about damaging the stain... so...

Monday, August 15th

Buffing and second coat of polyurethane applied...

... pretty!

The photo does not do the floors justice... however, since at the time this photo was taken we could not walk on the floors yet, my camera angle was a bit limited.

I kind of don't want to move much furniture back in... maybe just a chair and side table... but such is not the case, since this morning all the furniture we had moved into the dining room and kitchen, and more, moved back into the living room so that Rob could start sanding and staining the other half of the first floor...

August 6, 2011

heat + humidity = delay in wood floor installation... time for some serious A/C action

... the wood floor strips were delivered to the house Friday, July 29th. The plan was for them to acclimate over the weekend, and for Rob, the floor guy, to return Monday morning to start installation... Well, the crazy hot and humid heat wave hit and didn't stop... and we don't/didn't have A/C in the house... so when Rob returned Monday morning, he found the wood strips to have 10% to 11% moisture content... they are supposed to be at 5% to 6% MAX. As a result, installation was postponed until we get the moisture content down to where it needed to be...

Step One: Get a de-humidifier running 24/7 near the wood...

Luckily we had one in the basement (courtesy of the previous owner... best find in the house... it has come in handy so very many times!)... so we brought it up and started running the baby... it had to be emptied twice daily... that's how much moisture was in the air!

Step Two: Get window A/C units running pronto...

We had an old, somewhat functioning, ghetto window unit down in the basement, so we cleaned it off, brought it up and installed it temporarily in the gangway window... temporarily since our windows aren't meant for window A/C units. First off, they are too wide... if they were to be a 'permanent' fix/cooling means, we would need to construct side panels to fit b/w the A/C unit and the window jambs. The other problem is the sill... over 1/2 of the windows in the house are aluminum replacement windows... and they have this 2" lip on the sill which doesn't allow for the window A/C unit to sit properly. In any case, we 'temporarily' installed the window unit...

... the combination of the dehumidifier and the window A/C unit got the temperature down to 84 degrees and the humidity level to 51%... but that wasn't enough... ... we needed the humidity down to 45% or less.

Step Three: Time to get SERIOUS

... we ended up biting the bullet and getting a whole-house A/C unit installed. We were hoping to put it off until next summer... but since we had the duct work already installed, we just needed to get a new e-coil and outside unit...

... ha ha, "just".... funny.

Since our furnace was installed by Four Seasons, we opted to go with them for the A/C unit (plus they gave us a competitive price). We decided to place the unit in the gangway (it's compact and relatively quiet)... installation took about 4 hours...

... this is the first house I've lived in that has central A/C... air conditioning, I'm not crazy about it... I much rather have open windows with natural ventilation... however, on a 95 degree day with 70% humidity and a heat index of 115 degrees... it's love.

the front door

... gaps and chips have been repaired with bondo and wood filler...

... the existing bottom kick-plate panel was in horrid condition... beyond the abilites of bondo and wood filler aid... so, approximately 1/4" to 1/2" thickness was removed/cut/sanded-off and a new 'veneer' was installed.

The door hardware was also installed (finally!)...

... we purchased all of the hardware (for the front door, vestibule door and closet door) thru Clark & Barlow. We ended up going with Emtek... solid quality, clean design... and affordable. Given we had existing holes for the key lock and door knob, our options for the entryset were somewhat limited... our first choice was Lugano, a mortise entryset. We discovered it would have required re-working door quite a bit more, plus it was double the cost of a non-mortise lock, so sadly, it fell out of the running... We ended up getting the Orion in Satin Nickel, with a round knob vs a lever on the inside...

... it works well and looks nice... the lock still needs a bit of work, but it will be completed once they finish restoring the trim and door frame/jamb.

a hidden lintel, doors, and drywall...

As mentioned in the previous post, the new basement door just needed a lintel and some painting...

... we were at work while they were installing the lintel, so I wasn't able to take any photos of the installation... you will just have to trust me that there are two 4'-0" long steel angles, back to back, behind that brick, above the basement door... ... we also had them paint the door - Behr 'Black Bean'.

CORRECTION... I had them paint the door... and it was a mistake (you were right, Bryan)... they did a very sloppy job... plus they painted the inside of the door, and even though the color looks good on the outside, it's too dark for inside... oh well... something we'll have to tackle on a rainy day.

The front door is fully stripped... plus the glass was taken out... replacement glass should arrive mid-next week... in the meantime, some plywood sheets were tacked on temporarily...

... the locks and door knob were also removed while stripping... lock was replaced (upside down... wtf?)... but door knob was not, so Bryan had to fashion a temporary door knob out of a knotted dish cloth and duct tape... he's the engineer...

... it works!

Vestibule door was patched with bondo and wood filler, awaiting re-installation...

Stair installation is almost complete... wood paneling is pretty much stripped clean... except for the closet door...

... closet door still needs some cleaning up and new hardware.

Drywall is up, taped, mudded and primed... a huge feat since the heat and humidity were making mudding and priming quite difficult...

... getting there...

Subscribe to:

Comments (Atom)